In pipeline works, the application of large size pipelines is more common, mainly used in urban water supply, drainage, and the main pipeline of industrial production. According to different mediums, the usage of the valve body and internal parts will be different. For example, like corrosive medium or seawater, customers generally choose aluminum inner parts in bronze or PTFE coated. This article mainly introduces the application of large-size valves by urban water supply and drainage systems.

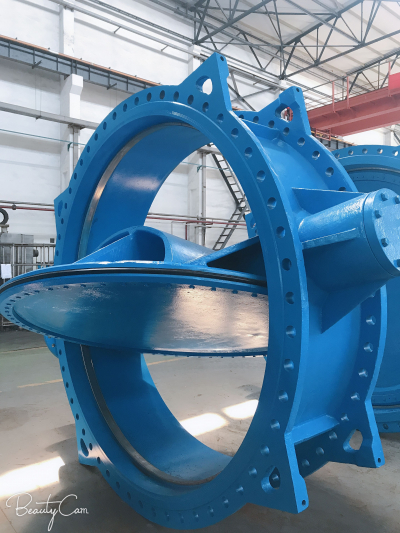

This is the double eccentric butterfly valve produced by Davan Flowtek:

In large-scale water supply pipes, most of them are mainly in low-pressure, but sometimes in high pressure also. We have produced the DN1500 double eccentric butterfly valve, ductile iron body and disc, SS304 retainer ring, EPDM sealing, SS316 body sealing belt, worm gear operation, PN25 pressure design. Please check the followed video:

In the general pipeline, PN10 or PN16 pressures are in common. Some pipe designers want to improve the coefficient of insurance, make sure the pipeline cannot be leakage during the unstable pressure output. They still chose PN10 or PN16 butterfly valves but the real pressure of the pipe is only 3-6 kg. So Davan Flowtek always suggests customers communicate with designers or constructors in advance, to confirm the connection and pressure. In this way, procurement costs can be reduced sometimes.

Generally speaking, there are two kinds of big-size butterfly valves that can be used in the pipeline, double flanged centric type butterfly valve, and double eccentric butterfly valve. Let us introduce the characteristics of these two valves as below:

Double Flange centric type Butterfly valve

As the name, the design structure of the flange centric butterfly valve is middle line form. That is, the valve disc and seal line in the middle of the valve body. The general material is ductile iron body and disc, EPDM lining, SS420 valve shaft, and wore gear operation. When the pipeline size exceeds DN800 and the pressure is PN16, the valve shaft can be replaced with SS431. This material has greater strength than SS 420. The design standard is BS5155, EN558 Series 13, and the flange connection standard can be DIN2501/EN1092PN10/16, ANSI CLASS 125/150

According to the requests by customers, the operation can be with electric actuator or pneumatic actuator. Like AUMA, ROTORK brand, or China local brand we used.

If you want to know more details of this product, you can contact us as followed:

If the size exceeds DN1200, we usually recommend a double eccentric butterfly valve. Because for a large size valve body, the cost of EPDM lining on the valve body will be very high. Such as the size in DN2200, PN10 pressure, if you choose double flange centric type butterfly valve, the price will be USD56000/SET, but if you choose double eccentric type, it is only USD27000/SET. The cost is at half level. And for later maintenance, Double eccentric valve costs are much lower than the centric type.

The following is a description of our double eccentric butterfly valves.

The sealing location and the valve disc of the double eccentric valve are not in the centerline position and have an offset angle, so it is called the double eccentric valve. The basic material is the ductile iron body, and disc, SS304 or SS316 valve body seal ring, SS420 or SS431 shaft, EPDM valve plate seal ring, carbon steel/SS304/SS316 retainer ring, worm gear, or electric actuator operation.

There are two types of valve body sealing:

1.Welded sealing on the valve body

It needs to make a groove on the valve body and then bead welding SS304 or SS316 in this groove. The last step is polishing to flat. This technology is relatively simple, and many well-known international brands are also using it, such as AVK valves and TECOFI valves companies. But this sealing form demands high-performance welding technology, there are many valve manufacturers in China which cannot finish this works very well. So during the using time, the valve body sealing surface will crack a little bit, so that impurities in the pipe may accumulate on the sealing surface, scrape the rubber seal on the valve plate and eventually damage the seal and leakage. In a sense, it will affect the using time of this welding sealing.

2.Rolling in sealing type

This technology is from the production process by Kubota from Japan, we have carried out a series of innovations and improvements in this process. Now, this valve is our featured product. The production process is to press the SS316 seal strip on the valve body with a special machine roller, and under the SS316 seal strip, there will be a hidden seal EPDM ring, which can ensure that the bottom end of the seal groove will not leak.

And because the stainless steel sealing belt is integrated, it will not crack during works. And this seal belt is slightly higher than the body cavity, so if there are impurities in the pipe, it will also pile up at the lower end of the seat belt, with no damage to the sealing surface. So the service life of the valve is greatly enhanced. According to experience statistics, the service life of this valve can reach 10-15 years. if you have more demand about this valve, you can contact us.

To sum up, it is a brief introduction about the large size valve, which produced by DAVAN FLOWTEK company. Davan Flowtek is not only focused on the production of valves, we can provide customers with quality solutions of the pipeline works, and help them to reduce more cost during the purchasing works from China. This is our works, and this is also our mission.

Leave A Comment