Project Description

ductile iron pipe water use iso 2531 EN545 2010, which can be used in water supply and drainage project.

ductile iron pipe water use iso 2531 EN 545 2010 featured character:

Joint- T type rubber gasket:

The installation of T type rubber gasket is quick simple, and convenient. Such gaskets can bear larger deflection angle and tolerance, lowering the technical requirement of installation. T type rubber gasket is a kind of self-sealed gasket, and the installation just requires putting the socket into the bell mouth and pressing the gasket tight, thus guaranteeing the sealing performance of gaskets.

Inner anti-corrosion layer:

the inner layers of ductile iron pipes are centrifugally sprayed with cement mortar. Cement lining complies with the international standard ISO 4179, ensuring the mortar strong and smooth. The motor coating will not fall off or foul, and its thickness is even, ensuring the drinking water transferred by the pipes get good protection.

Protective coating: The zinc spraying of ductile iron pipes could protect the pipes proactively through the

electrochemical effect of zinc and iron. With the high chlorinated resin paint, the pipes will get enhanced anticorrosion

protection.

The surface zinc spraying of each pipe is not less than 130 g/m2, and complies with ISO 8179 standard. We can also increase the zinc spraying thickness or spray zinc & aluminum alloy layer according to the customers ‘demand.

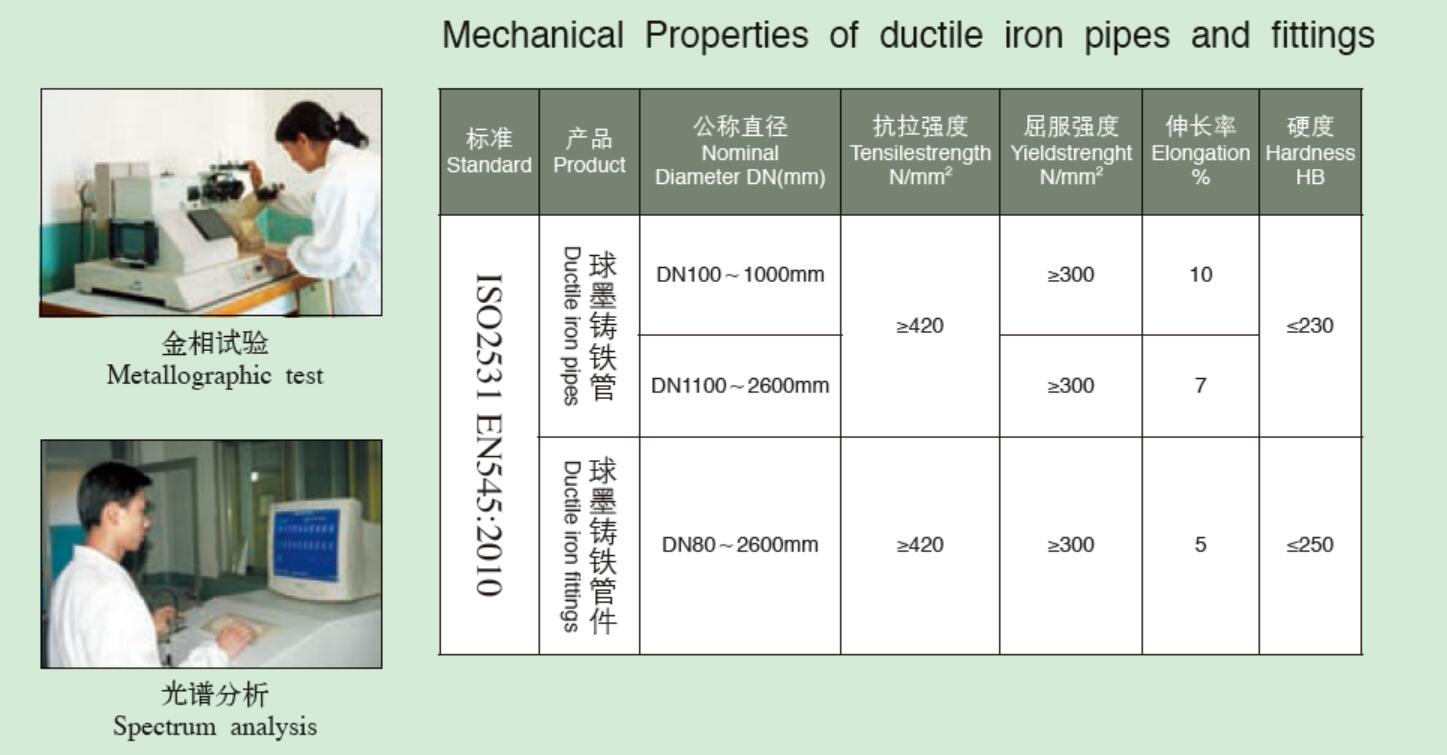

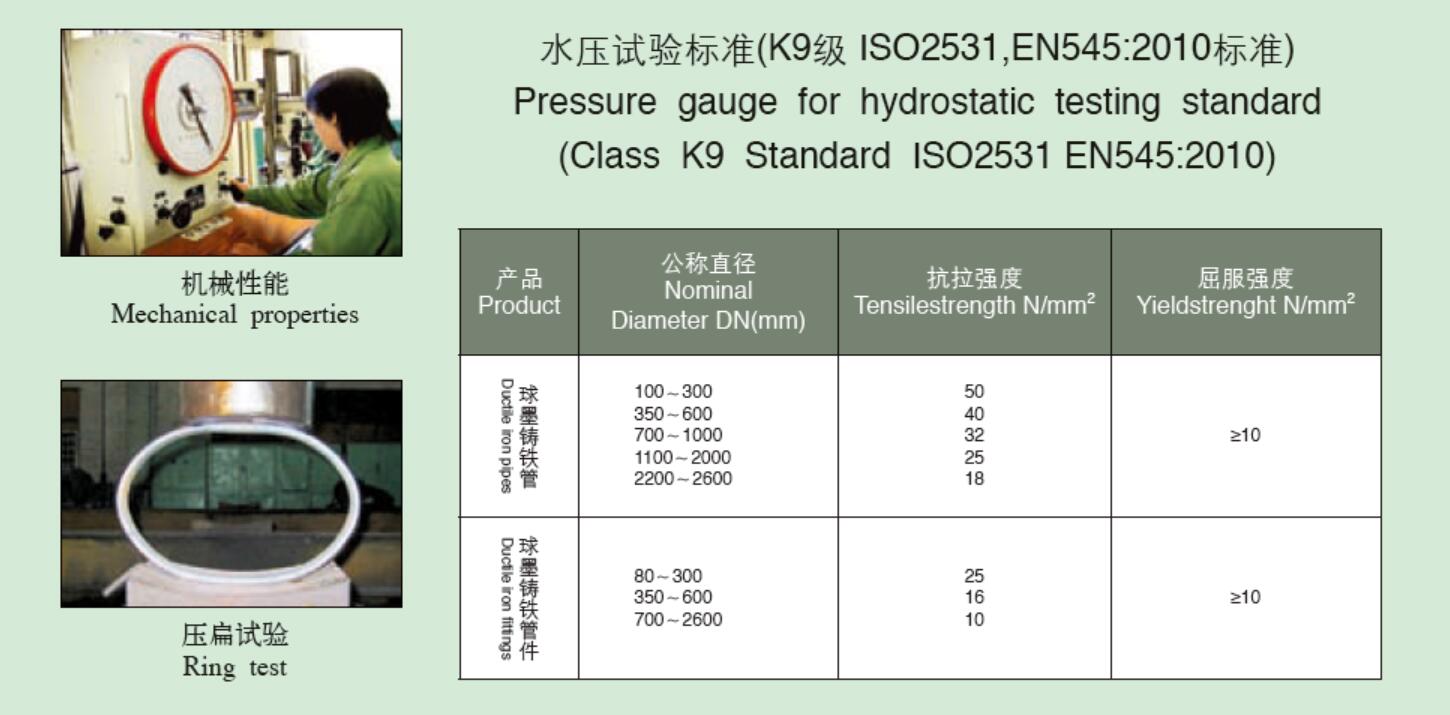

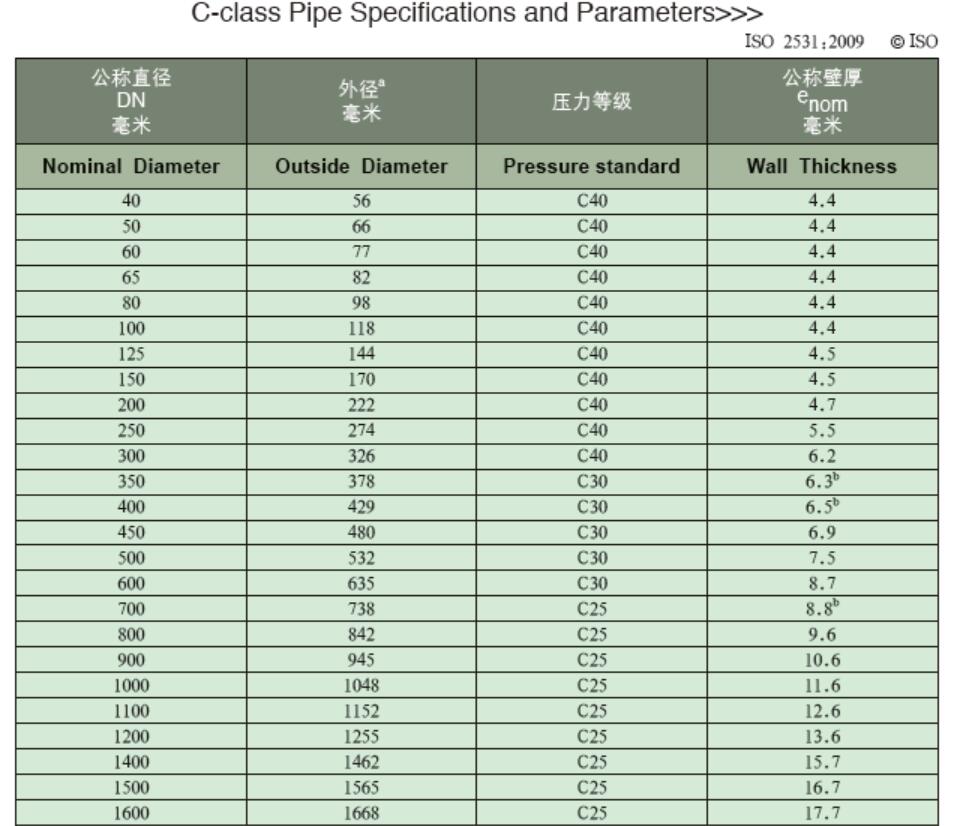

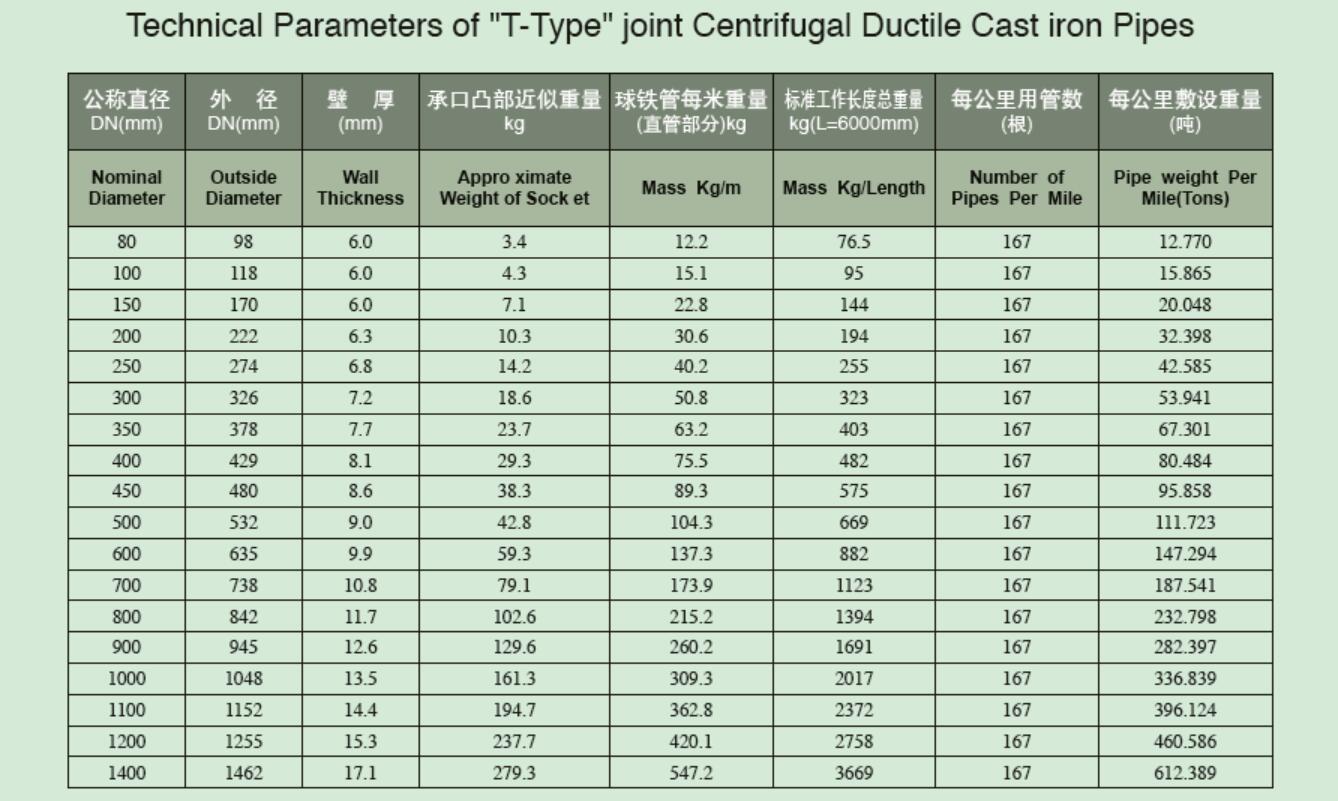

ductile iron pipe water use iso 2531 EN545 2010 Specification

Joint Structure:T-type joint and Restrained pipe joint

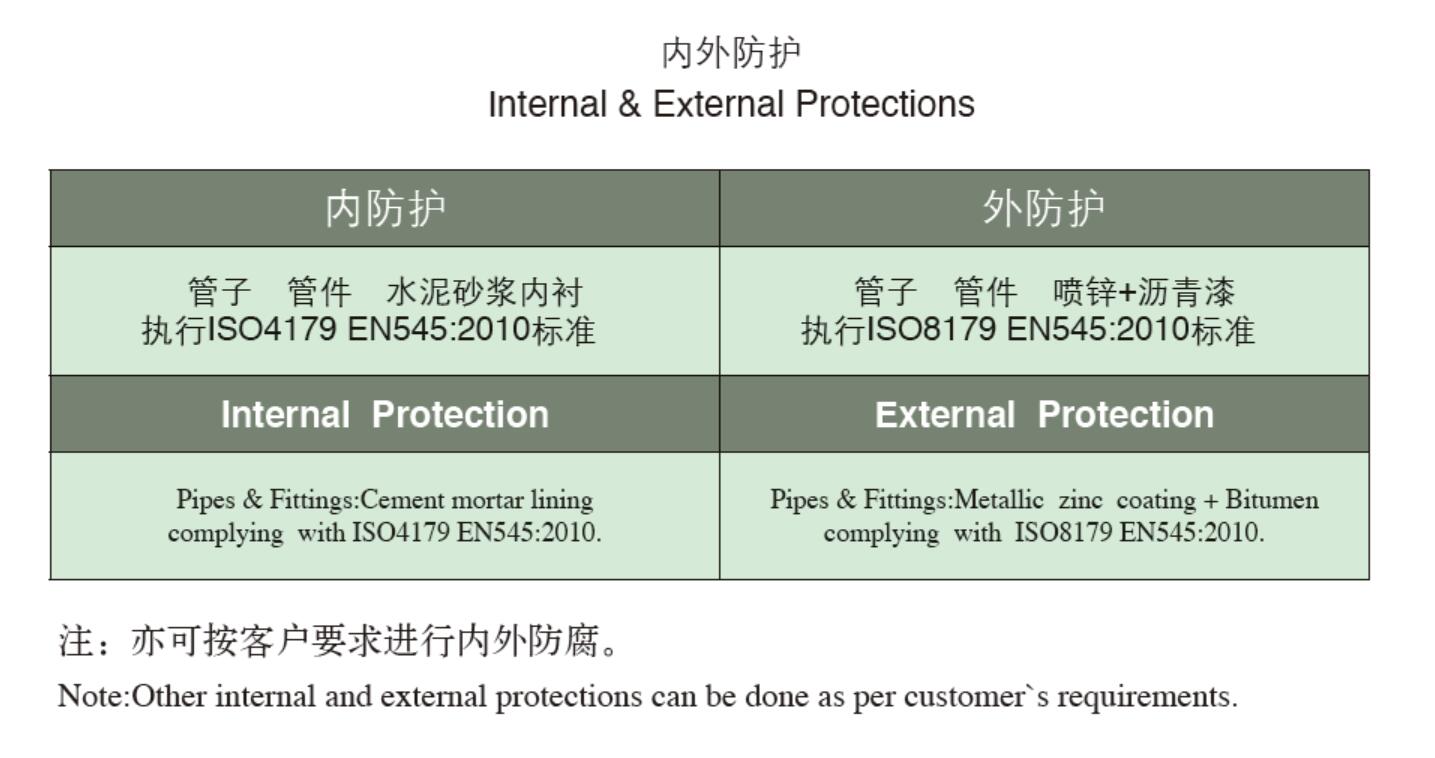

Internal and external protections:

Internal: Cement mortar lining complying with ISO 4179 EN 545:2010

External: Metallic zinc coating + bitumen complying with ISO 8179 EN 545:2010

Others: FEB coating/Epoxy painting/ 3 PE coating